Our know-how gathered on the race-track created the technical premises to develop a range of add-on electronic modules for every need: this is the winning background allowing Rapid Bike to be considered as a leader in the field of motorbike engine calibration.

Rapidbike project - developed thanks to preceding experiences gained in the motorbike sector – officially comes to light in 2004 with the objective of offering add-on modules for fast adjustments of the engine management without interventions on the original ECU

RapidBike line now includes solutions for any need and requirement:

• RAPID BIKE EASY, equipped with a microprocessor managing directly the lambda sensor signal to optimize the air/fuel ratio, improve the engine efficiency and eliminate the torque and power gaps typical of the low and medium rpm.

• RAPID BIKE EASY, equipped with a microprocessor managing directly the lambda sensor signal to optimize the air/fuel ratio, improve the engine efficiency and eliminate the torque and power gaps typical of the low and medium rpm.

• RAPID BIKE EVO, that puts in your hands total control of fueling operations as it is directly connected to all stock injectors (up to eight) while managing at the same time the corresponding air/fuel ratio. In this way the carburetion values can be modified throughout the entire engine power delivery curve.

• RAPID BIKE RACING that represents the highest level of technology available for reaching top performance, offering the widest range of solutions for demanding professional track riders and street users. Starting from the new standards set by Rapid Bike EVO, RACING module is designed to manage additional and innovative features setting new and unmatchable standards within the competitive arena.

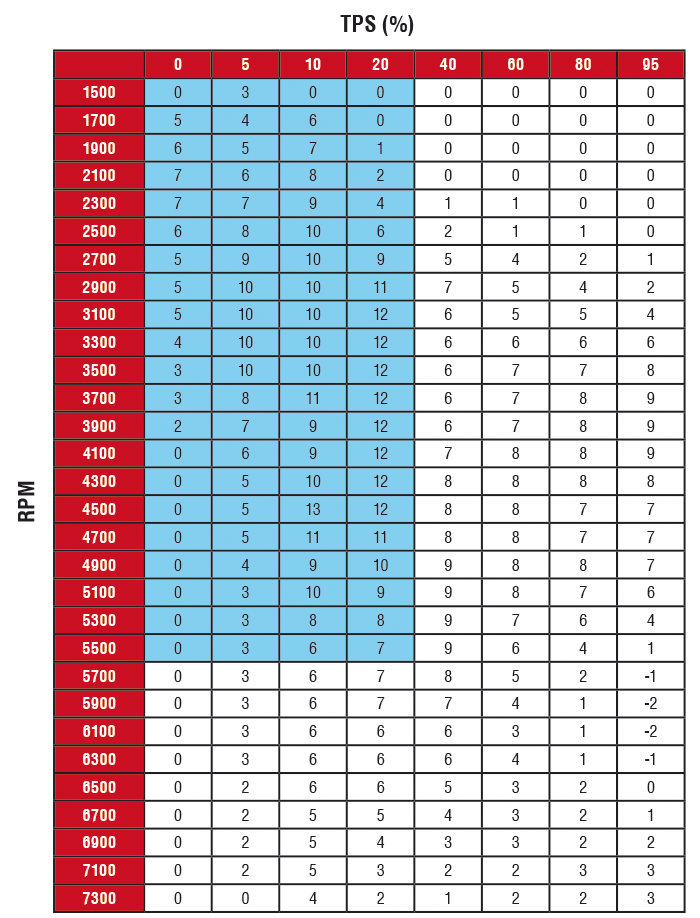

Take a close look at the map values*: all other brands of add-on modules claim to modify the injection values, but in reality Rapid Bike is the only one allowing you to take action and reach consistent results with re-mapping the most critical section of the power delivery curve, that is the range of low and medium rpm where the lambda sensor is in full control of fueling parameters.

Take a close look at the map values*: all other brands of add-on modules claim to modify the injection values, but in reality Rapid Bike is the only one allowing you to take action and reach consistent results with re-mapping the most critical section of the power delivery curve, that is the range of low and medium rpm where the lambda sensor is in full control of fueling parameters.

The graph’ blue area is defined by other brands as ‘closed loop area’ and as a matter of fact this section remains ‘off-limits’ for the rider since no real modifications of injection values are allowed.Rapid Bike technology puts you in full control of the game without any sort of limitations, offering you a powerful tool to be in charge of improving your bike performance in every riding conditions. Rapidbike software is for windows operation system only.

RAPID BIKE REVOLUTION FOR LAMBDA SENSOR MANAGEMENT

The amount of intake air coming through the engine and mixed with fuel is affected by different factors such as altitude, temperature and pressure: this is the reason why bike performance is likely to change considerably with unpleasant effects for the rider.

LAMBDA SENSOR: WHY IT WAS CONSIDERED AS A PROBLEM

LAMBDA SENSOR: WHY IT WAS CONSIDERED AS A PROBLEM

As the electronic became more and more popular for engine management, it was necessary to use a number of sensors to control the fuel amount being injected and maintain a balanced carburetion. The bike manufacturers adopted the lambda sensor installed on the exhaust system to monitor the carburetion values in order to comply with increasingly restrictive anti-pollution regulations – consequently, this system represented a real constrain for the engine as it was forced to run with very lean fuel mixture.

Lambda sensor measures the air/fuel ratio showing the amount of air detected in the exhaust gases for each unit of gasoline. The OEM ECU (Engine Control Unit) managing the engine receives the air/fuel measure from the lambda sensor to compare it with the value pre-set in its memory; in this way the ECU can determine whether the air/fuel ratio is too lean or too rich and takes the proper measures to modify the amount of gasoline being injected. This is why the lambda sensor is perceived as a problem generating some major inconvenience such as engine poor reaction and sudden power gaps.

RAPID BIKE PROVIDES THE SOLUTION!

Rapid Bike technology stands out to be really innovative since it performs the modulations of lambda sensor signal rather than trying to eliminate it – the modulation is dynamic and fully compatible with the new injection values set by the add-on module. This solution helps the whole system (OEM ECU + Rapid Bike add-on module) to be more reliable, and to prevent the benefits of improved fueling from being perceived as a mistake to be fixed.

As a matter of fact, Rapid Bike module changes the amount of injected fuel (as it controls directly up to 8 injectors) while modulating at the same time the lambda sensor signal in such a way that OEM ECU will not detect any difference in the air fuel ratio, rather it will read a value matching the pre-set AFR standards. This innovative solution puts ‘out of the game’ poor and inefficient attempts to eliminate the lambda sensor signal with devices no longer applicable.

AUTO-ADAPTIVE FEATURE: OUR EXCLUSIVITY

Rapid Bike additional advantage is the ability to stabilize the best fueling values reached with using the add-on module, a system which is similar to the ECU working criteria. The new and innovative autoadaptive feature allows Rapid Bike module to compare the air/fuel ratio target value (set within the module’s map) with the signal reported by the stock lambda sensor. The result of this continuous comparison determines whether the fuel being injected needs to be increased or decreased, and secure the engine always delivers the best performance.

FREE YOUR MIND FROM THE OLD MYTH OF A SET INJECTION MAP

This advantage is even more useful when performing some consistent modifications to the bike (such as the installation of a free-flow air filter or a racing exhaust system) requiring the injection map to be modified – Rapid Bike module is able to develop and implement these changes automatically, while the rider is using the bike.

Rapid Bike overcomes the “old” idea of an injection map conceived as a value remaining fixed overtime. Our add-on modules offer the unique feature to develop an injection map and keep it constantly

adjusted making the proper modifications without any need of external operations. Such a technology is so far advanced that a Rapid Bike module will complete the auto-remapping injection process within 200 km ride even in case of starting with a ‘zero’ value map.

* This chart refers to the injection map of a DUCATI HYPERMOTARD 796 (2010 model)

| REVOLUTION IS IN YOUR HANDS! |

YouTune is the new handlebar mounted controller putting a technological revolution in your hands. A compact and innovative calibration device allowing to customize your bike’s performance in real time, whether you are on the street or on a race track.

YouTune is the new handlebar mounted controller putting a technological revolution in your hands. A compact and innovative calibration device allowing to customize your bike’s performance in real time, whether you are on the street or on a race track.

To be purchased as a separate accessory for installation with Rapid Bike EVO and Rapid Bike RACING modules.

- AIR/FUEL PARAMETERS MANAGEMENT to optimize carburetion in real time thanks to the possibility of changing auto-adaptive target value for fueling corrections

- ELECTRONIC QUICK SHIFTER MANAGEMENT to change the injection kill time

- SHOWING MAIN ENGINE PARAMETERS including RPM, TPS, AFR, OEM Lambda Status, etc.

- ENGINE BRAKE MANAGEMENT* to change and modulate the effects of engine brake

- TRACTION CONTROL ACTIVATION AND MANAGEMENT* to enable Traction Control function and change all related settings to increase or decrease its effectiveness

- LAUNCH CONTROL ACTIVATION AND MANAGEMENT* to enable and modulate the settings allowing to perform a ‘flying start’

UP/DOWN SHIFT ASSIST

New UP/DOWN SHIFT ASSISTrepresents a big step forward in terms of quick-shifting solution offered by RAPID BIKE thanks to a further technological development toperform up-shifting (traditional mode) as well as down-shifting operations (the so-called ‘blipper’, available only for bike models equipped with ‘ride by wire’). A new device reaching unmatched technical standards designed to deliver outstanding performance to race track enthusiasts and further improve riding experience.

New shifting device exchanging information with EVO and RACING add-on modules via CAN-bus allowsto perform auto-calibration of shifting kill-time in relation to the pressure applied in both directions, upper and lower gear, while matching the engine peculiar configuration. A greater bike’s handlebar control and lower mechanical stress, granted by the unique ‘self-learning’ process, improve considerably driving safety.

This new accessory actually inherits all the benefits and advantages of previous ‘All around quick shifter sensor’ including full compatibility with YouTune to manage pressure level applied for activating shifting operations. Another additional feature to be managed via YouTune is the modulation of engine response sensitivity when opening throttle control.